Autoclaved Aerated Concrete (AAC) blocks are a versatile, lightweight, and sustainable building material used widely in construction.

0

0Autoclaved Aerated Concrete (AAC) blocks are a versatile, lightweight, and sustainable building material used widely in construction.

Product Description

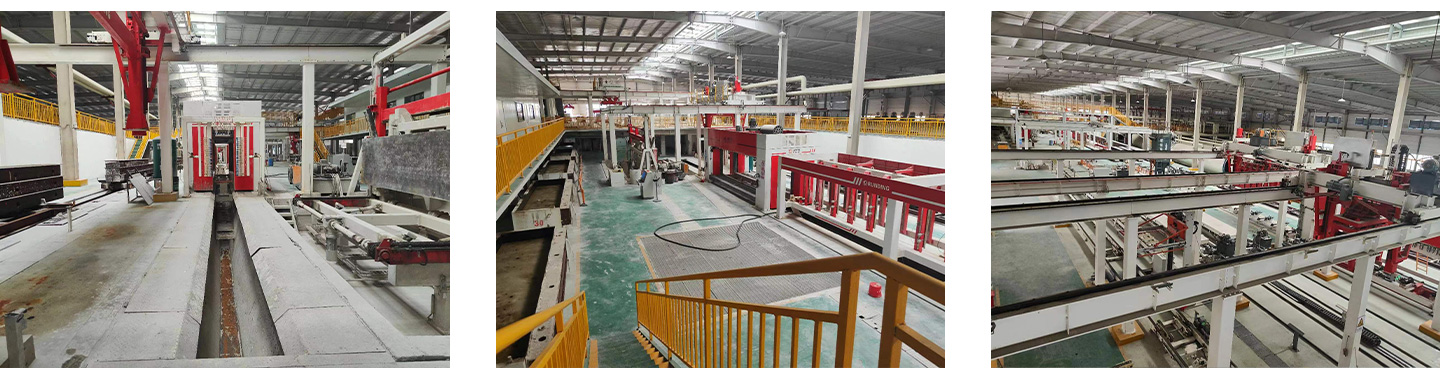

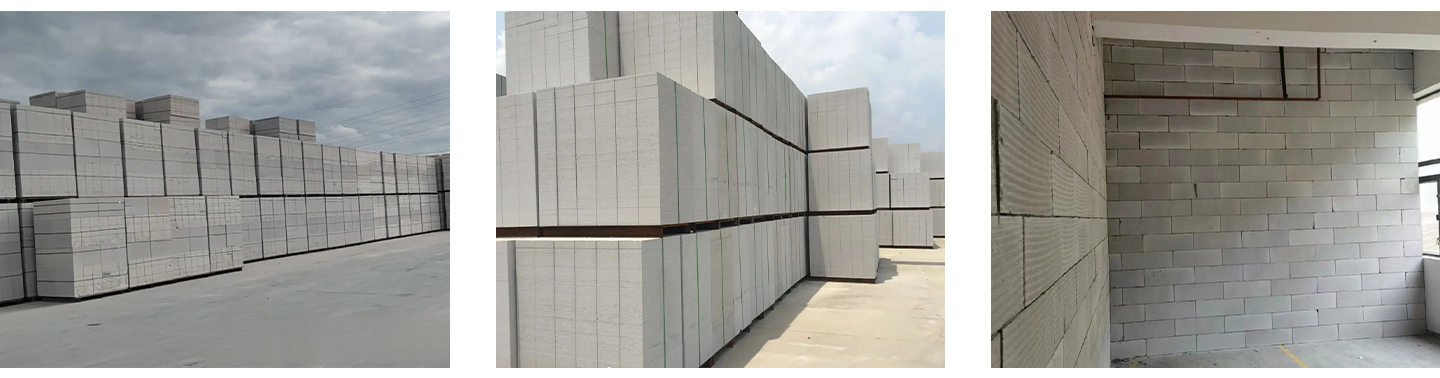

1. Product OverviewAAC blocks, also known as Autoclaved Aerated Concrete blocks, are manufactured using a mixture of silica (sand or recycled fly ash), lime, cement, water, and aluminum powder. This combination undergoes autoclaving, a high-pressure steam curing process, which imparts superior strength and stability to the blocks. AAC blocks are renowned for their light weight, thermal insulation properties, and eco-friendliness, making them ideal for various construction applications, including residential, commercial, and industrial buildings.

2. Key Features

● Lightweight: Significantly lighter than traditional concrete blocks, making handling and transportation easier.

● High Strength: Despite their light weight, AAC blocks offer impressive compressive strength, suitable for load-bearing applications.

● Thermal Insulation: Excellent thermal properties reduce heating and cooling costs, contributing to energy efficiency.

● Fire Resistance: Non-combustible and can withstand high temperatures, providing enhanced fire safety.

● Sound Insulation: The porous structure provides effective sound insulation, creating quieter indoor environments.

● Eco-Friendly: Made from non-toxic ingredients and recyclable materials, minimizing environmental impact.

Parameters

1. Physical and Mechanical Properties

● Density: 500-700 kg/m³

● Compressive Strength: 3.5-5.5 MPa

● Thermal Conductivity: 0.10-0.14 W/(m·K)

● Water Absorption: 20-30%

● Fire Rating: Up to 4 hours

● Drying Shrinkage: ≤0.6 mm/m

2. Dimensional Specifications

● Standard Size: 600 x 200 x 100 mm, 600 x 200 x 150 mm, 600 x 200 x 250 mm (custom sizes available)

● Thickness Options: 75 mm, 100 mm, 150 mm, 200 mm, 250 mm

3. Application Areas

● Internal and External Walls: Suitable for both load-bearing and non-load-bearing walls.

● Flooring and Roofing: Ideal for floor and roof panels due to their lightweight and insulating properties.

● Acoustic Barriers: Effective in creating sound barriers in residential and commercial buildings.

Usage Instructions

1. Construction Guidelines

● Masonry: Use appropriate adhesive or mortar to ensure strong bonding between blocks. Maintain vertical and horizontal alignment during construction.

● Surface Finishing: AAC blocks can be finished with various plasters, paints, or tiles for enhanced aesthetics and protection.

● Cutting and Shaping: Easily cut and shaped with standard tools, allowing for on-site adjustments and custom designs.

2. Storage and Handling

● Storage: Store in a dry, covered area to prevent moisture absorption and maintain quality.

● Handling: Handle with care to avoid damage. Utilize pallets and protective covers during transportation.

Market Potential

With the growing emphasis on sustainable and energy-efficient building practices, the demand for AAC blocks is on the rise. Their unique combination of strength, insulation properties, and environmental benefits makes them a preferred choice for modern construction projects globally.

Example Comparison: Common AAC Parameters vs. Custom Data

Parameter | Common Value | Custom Data Provided |

Density | 500-800 kg/m³ | 500-700 kg/m³ |

Compressive Strength | 2.5-4 MPa | 3.5-5.5 MPa |

Thermal Conductivity | 0.12-0.20 W/(m·K) | 0.10-0.14 W/(m·K) |

Water Absorption | 25-35% | 20-30% |

Drying Shrinkage | ≤0.8 mm/m | ≤0.6 mm/m |